Your cart is currently empty.

Description

Specification

Contact

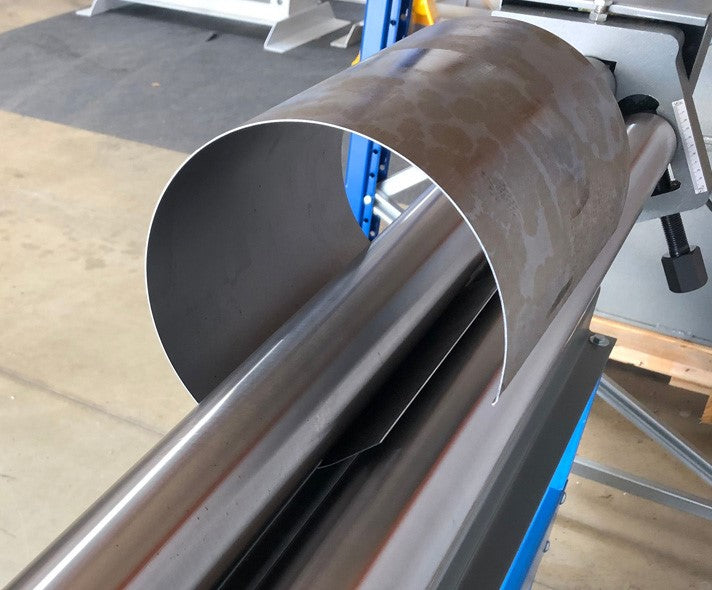

- Plate Rolling Capacities; the narrower the width of the plate entering the machine, the thicker the plate that can be rolled, the type and grade of the material determine both the largest dimensions that can be rolled and the minimum radii that can be rolled. For harder materials, maximum heavy plate rolling dimensions become smaller and minimum radii become larger.

- Max Rolling Thickness we can do is up to 4 mm and 2000 mm sheet width, Minimum Roll Diameter of 350 mm.

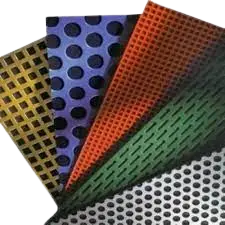

- we can roll perforated metal sheets or sheets with special cutouts.

- As needed, we can roll the metal sheet into the cylinder, and install angle rings with Van Stone flanges.

- We can brace steel sections to hold their radius during shipment (a process called spidering) or create custom carriers to otherwise facilitate shipment.

- To complement our custom heavy steel plate rolling services, we offer a variety of secondary services, like Saw cutting, Torch cutting, Plasma cutting, and Welding (MIG, TIG, track, or submerged arc).

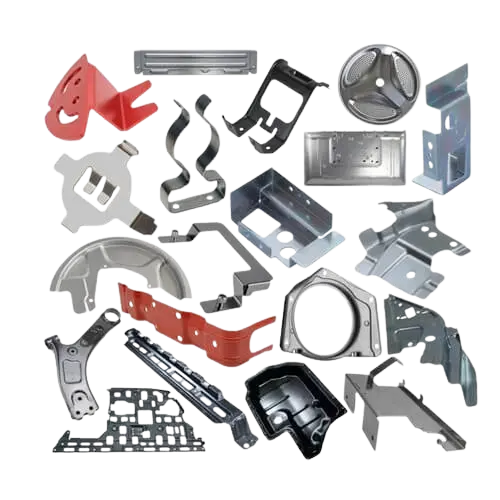

- While there are countless applications for rolled plate and rolled sheet metal, we encounter certain applications more than others. Our heavy plate rolling services are most often used to create components for metal duct work, circular tank walls, machine housings, piping, stacks, molds, and bridges, with both hot and cold bending services available to satisfy Department of Transportation requirements.

- Plate rolling can be viewed as an art and with an experienced operator that understands the equipment, the material and the application, the outcome can be very profitable.

- Plate rolls are used to fabricate many components such as tanks, pressure vessels, pipes and just about any other cylindrical, oval or out of round shapes made with metals. Most plate rolls can adjust the top roll to a tilt position which allows products to be produced with cone geometries.

- When it comes to choosing a plate roll, alongside choosing the correct type it’s imperative that you get the correct size. If the size of the plate roll doesn’t match your application, you’re going to waste your money unnecessarily.

- How to Select the Plate Roll Size for Your Application; you’ll need to consider the types of applications that you are intending to use it for. Bending Length, Minimum Diameter, Bending Capacity, Pre-Bending Capacity,

Plate Rolling Service

Specifications

Contact Us

For more information and assistance please contact us at:

Email: Info@taimco.ca

Phone: 1(289)999-2334

Email: info@taimco.ca

Get a quote in 24 hours!