Your cart is currently empty.

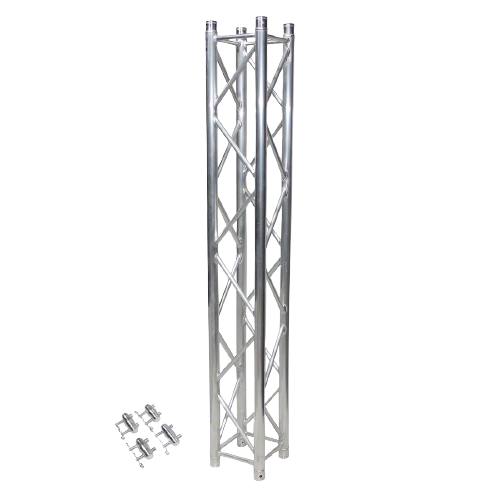

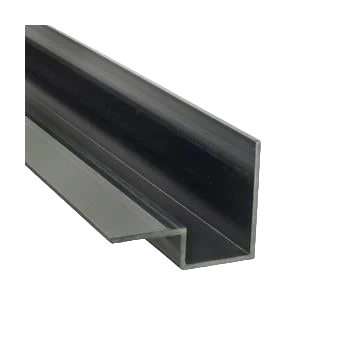

U Channel Bending

Free Delivery

US & Canada

*Additional handling charges may apply*

-

- Precision Bending: Achieve exact bends with minimal tolerance, ensuring perfect fit and function.

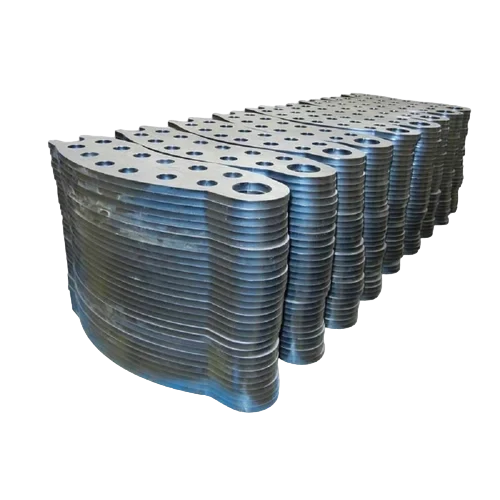

- Versatile Material Handling: Capable of bending a wide range of materials including aluminum, steel, and stainless steel.

- Customizable Solutions: Tailored bending services to meet unique project requirements.

- Advanced Technology: Utilization of state-of-the-art press brake machines for efficient and accurate bending.

- Quality Assurance: Rigorous quality control processes to ensure the highest standards are met.

-

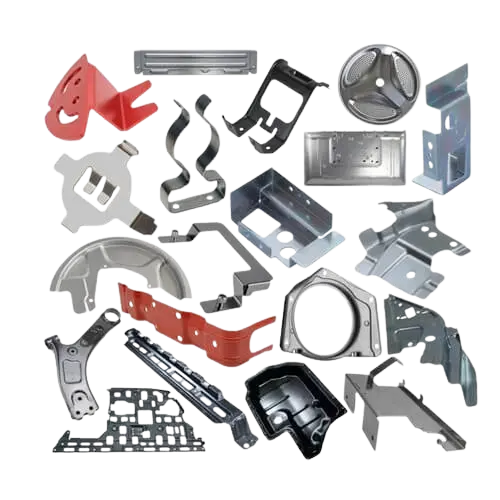

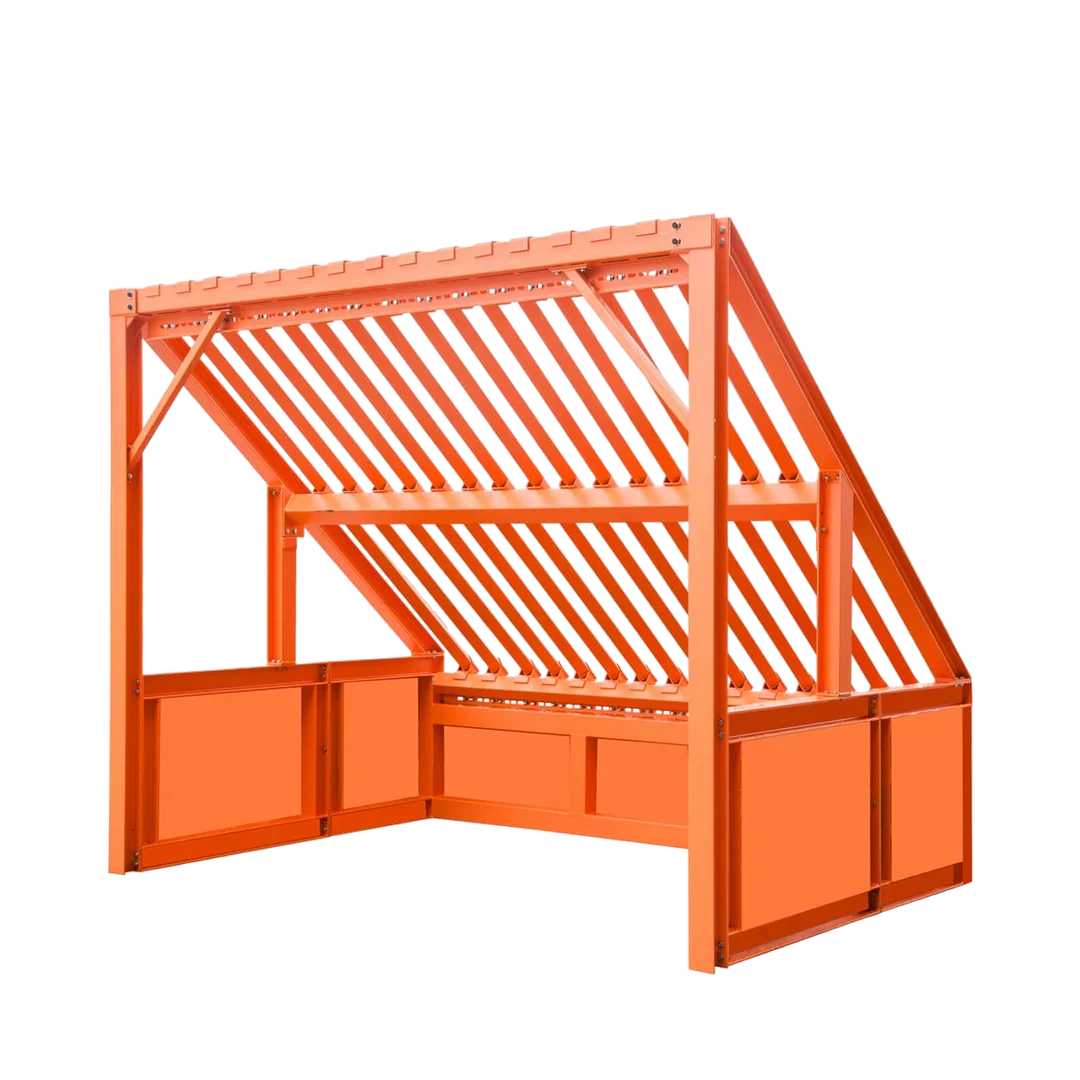

- Manufacturers: Providing components for machinery, equipment, and structural applications.

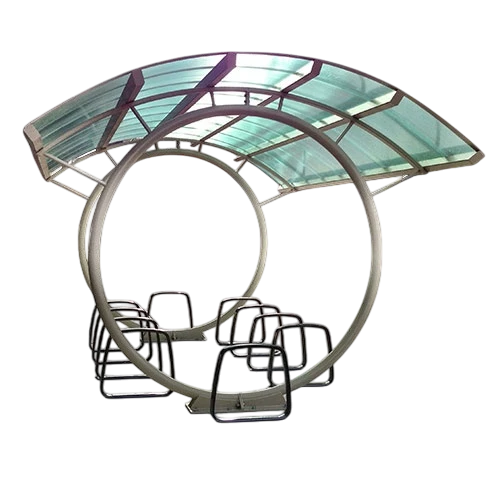

- Construction Companies: Supplying U channels for framing, support structures, and decorative elements.

- Automotive Industry: Delivering precision-bent channels for vehicle frames and components.

- Aerospace Sector: Offering high-quality bends for aircraft structures and parts.

- Architectural Firms: Creating custom U channels for architectural designs and installations.

-

- Contact us today for a Quote and let us help you bring your projects to life with precision and excellence.

- The Raw Material Cost is extra and will be added to the Pending service cost based on the Metal type and thickness.

-

- You Can Email Us at Info@taimco.ca for any more information.

- Phone: +12899992334

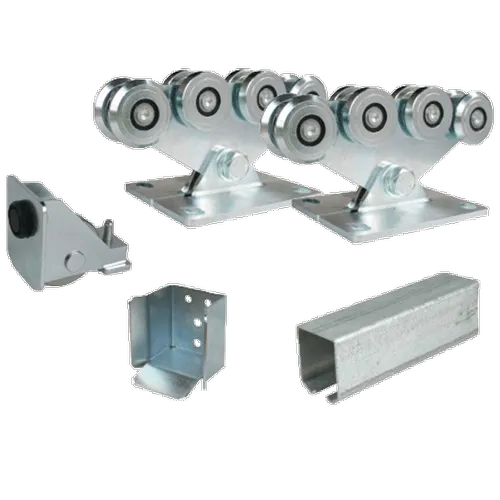

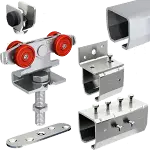

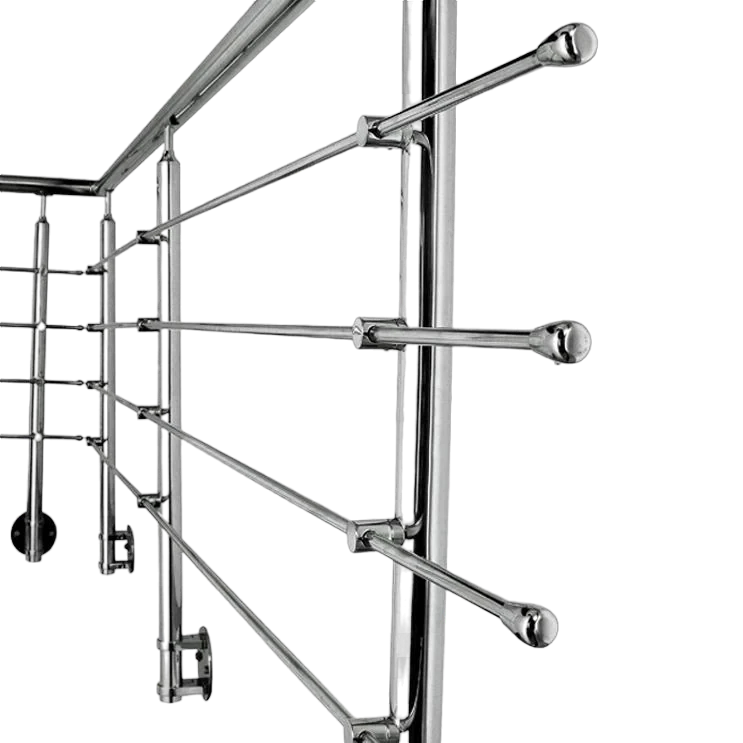

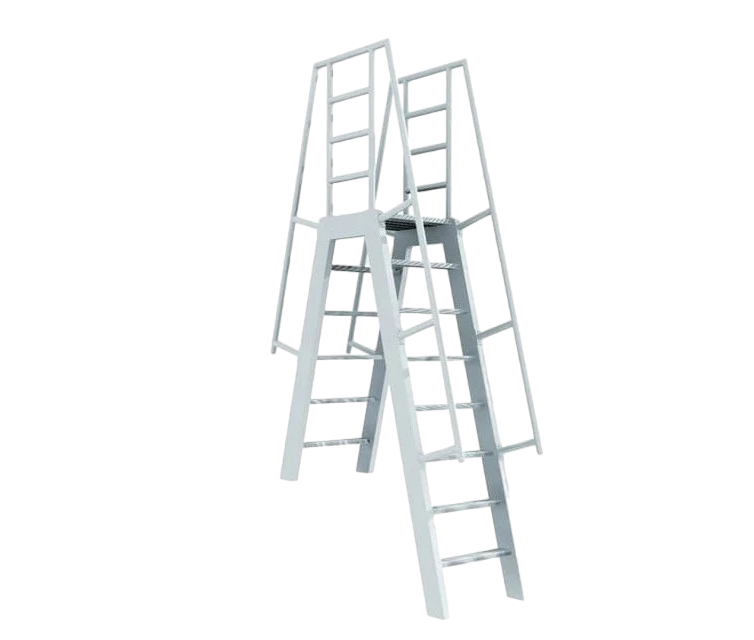

U Channel Bending Service

Our U Channel Bending service provides precise and high-quality bends for U-shaped channels, tailored to meet the specific needs of various industries. Utilizing advanced press brake machines, we ensure accuracy and consistency in every bend, delivering components that meet the highest standards of quality and performance.

Key Features:

Who We Are Servicing: We cater to a diverse clientele, including but not limited to:

Experience the difference with Taimco:

Dear valued customer,

We want to ensure your satisfaction every step of the way. As you may know, additional shipping charges are sometimes applied by third-party shipping companies for oversized or heavy items. These fees are based on factors like excess length, weight, and handling requirements.

Please rest assured that we do not profit from these charges; they are entirely passed on from the shipping companies. Our commitment to free shipping remains unwavering, and we appreciate your understanding.

Thank you for choosing us!

Email: info@taimco.ca

Get a quote in 24 hours!