Your cart is currently empty.

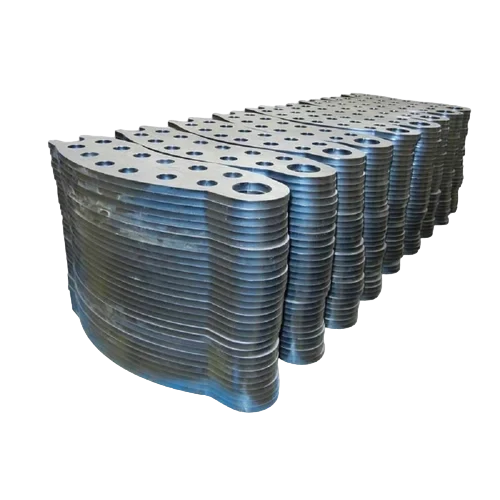

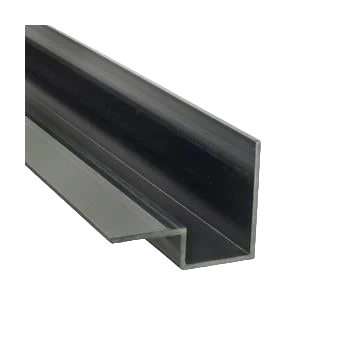

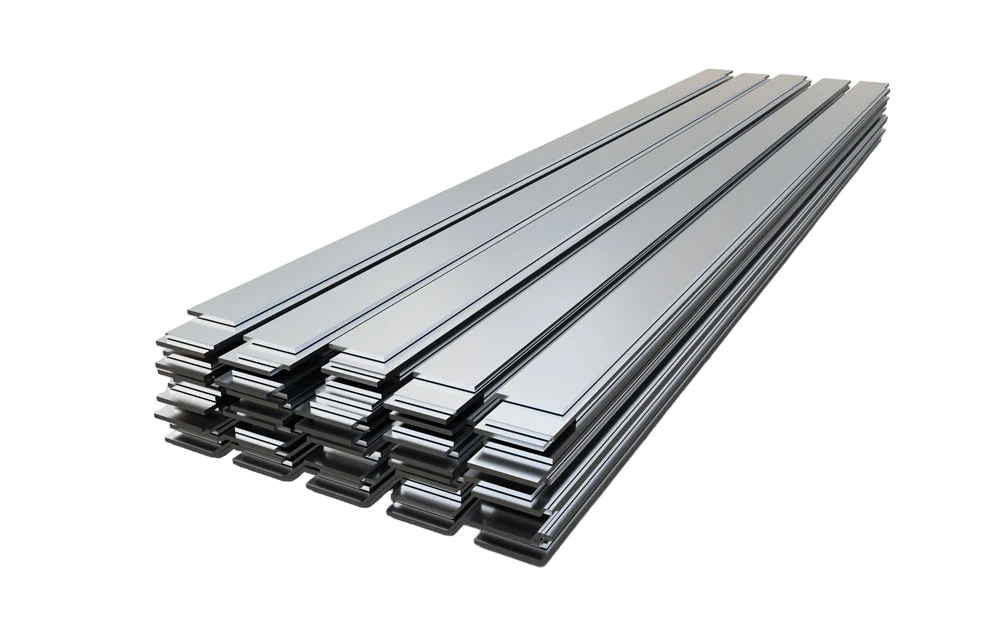

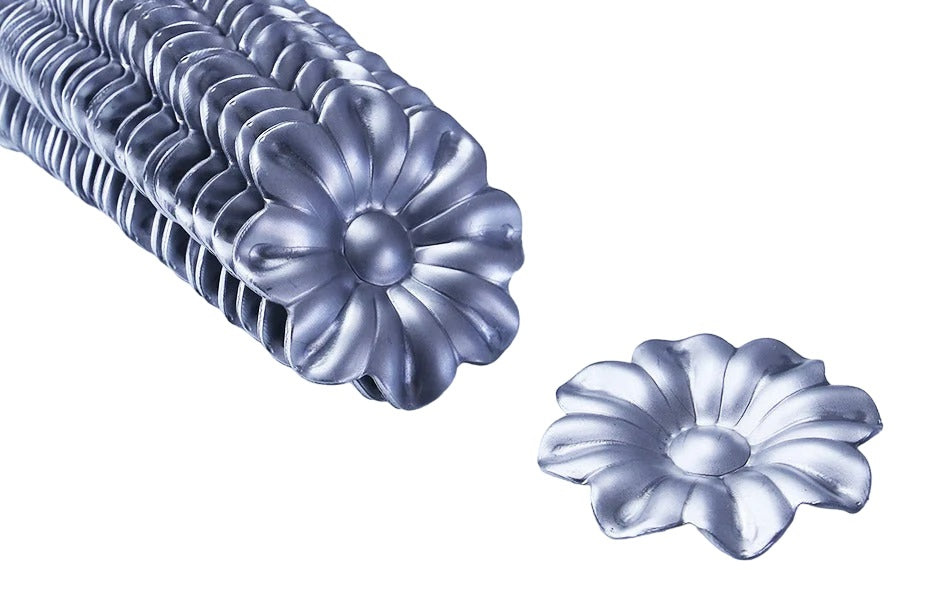

Metal Stamping

Free Delivery

Canada & USA

*Additional handling charges may apply*

-

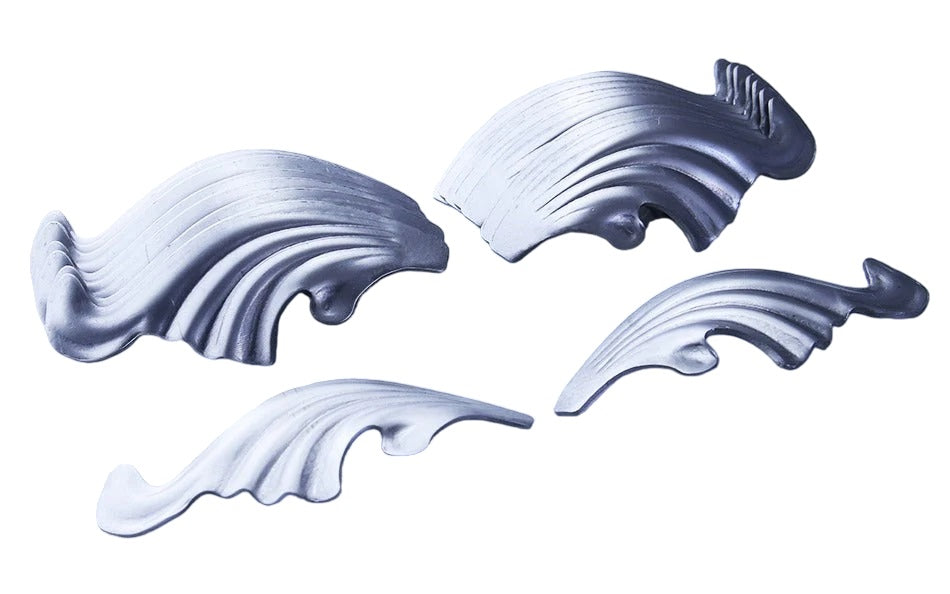

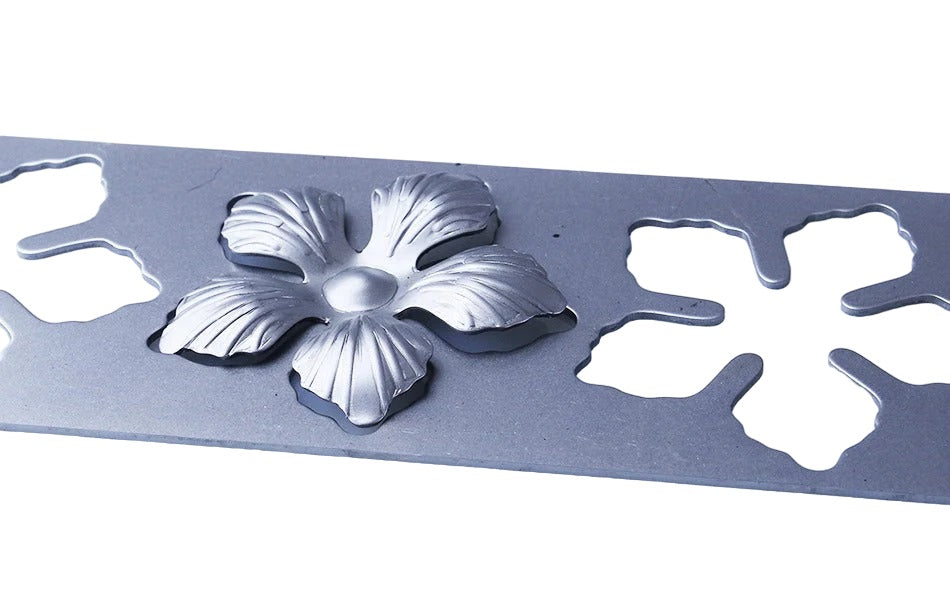

- Precision and Accuracy: Metal stamping allows for the creation of complex and intricate designs with high precision.

- High Efficiency: The process is highly efficient, enabling the production of large quantities of parts in a short time.

- Cost-Effective: Metal stamping is cost-effective, especially for high-volume production runs.

- Versatility: It can be used with various metals, including steel, aluminum, copper, and more.

- Consistency: Ensures uniformity and consistency across all produced parts.

- Customization: Offers the ability to create custom shapes and sizes to meet specific requirements.

-

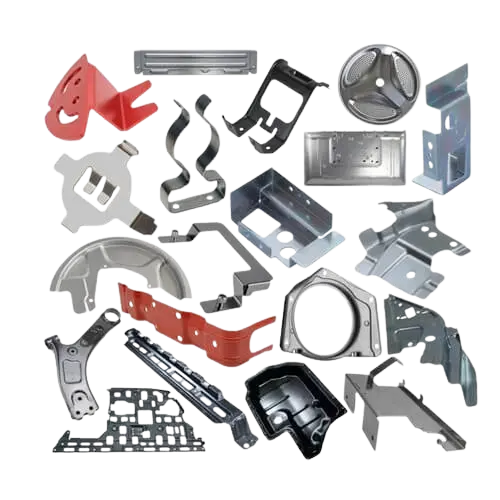

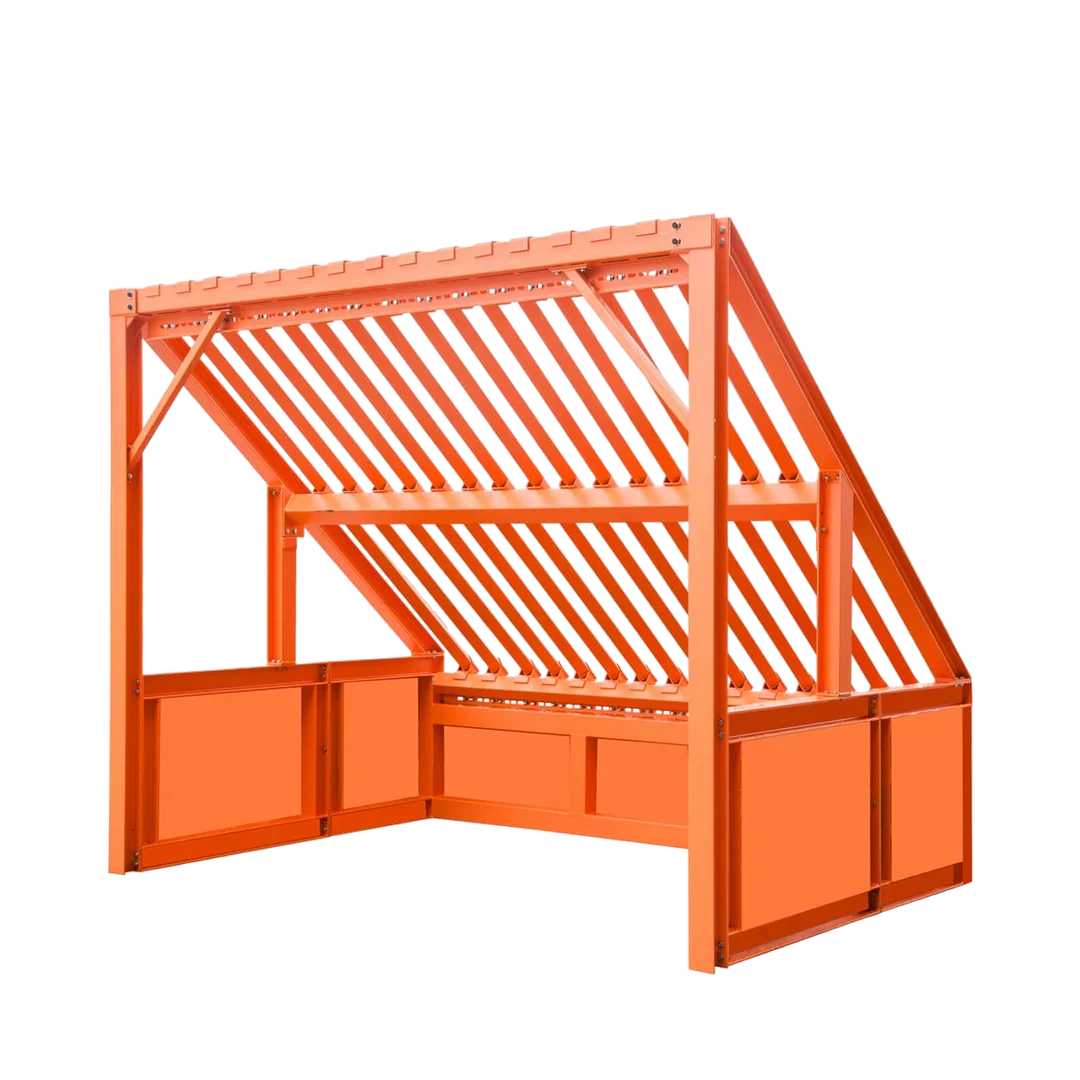

- Automotive: Producing components like brackets, clips, and engine parts.

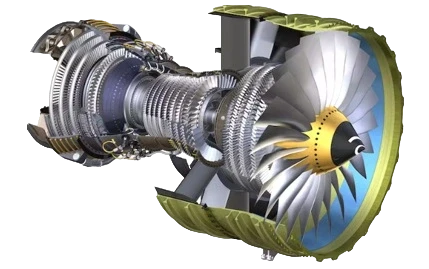

- Aerospace: Manufacturing parts that require high precision and durability.

- Electronics: Creating components such as connectors, terminals, and shielding.

- Medical: Producing medical devices and equipment parts.

- Appliances: Manufacturing parts for household appliances.

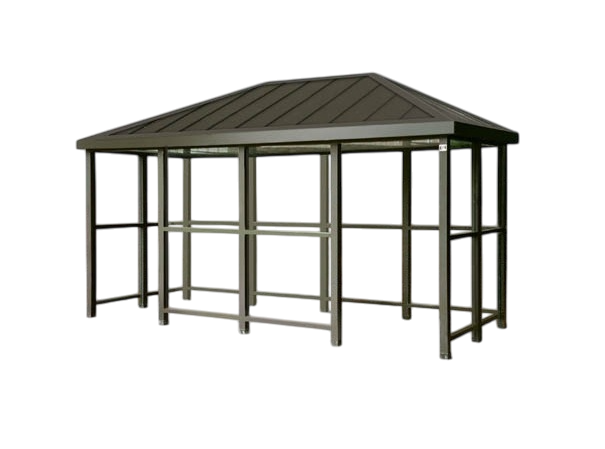

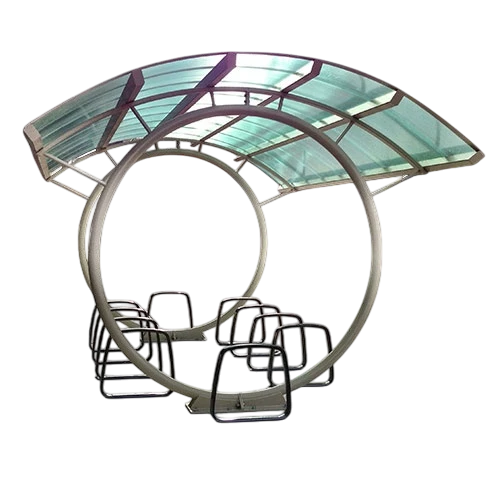

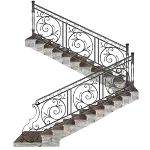

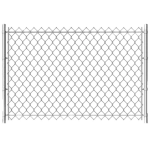

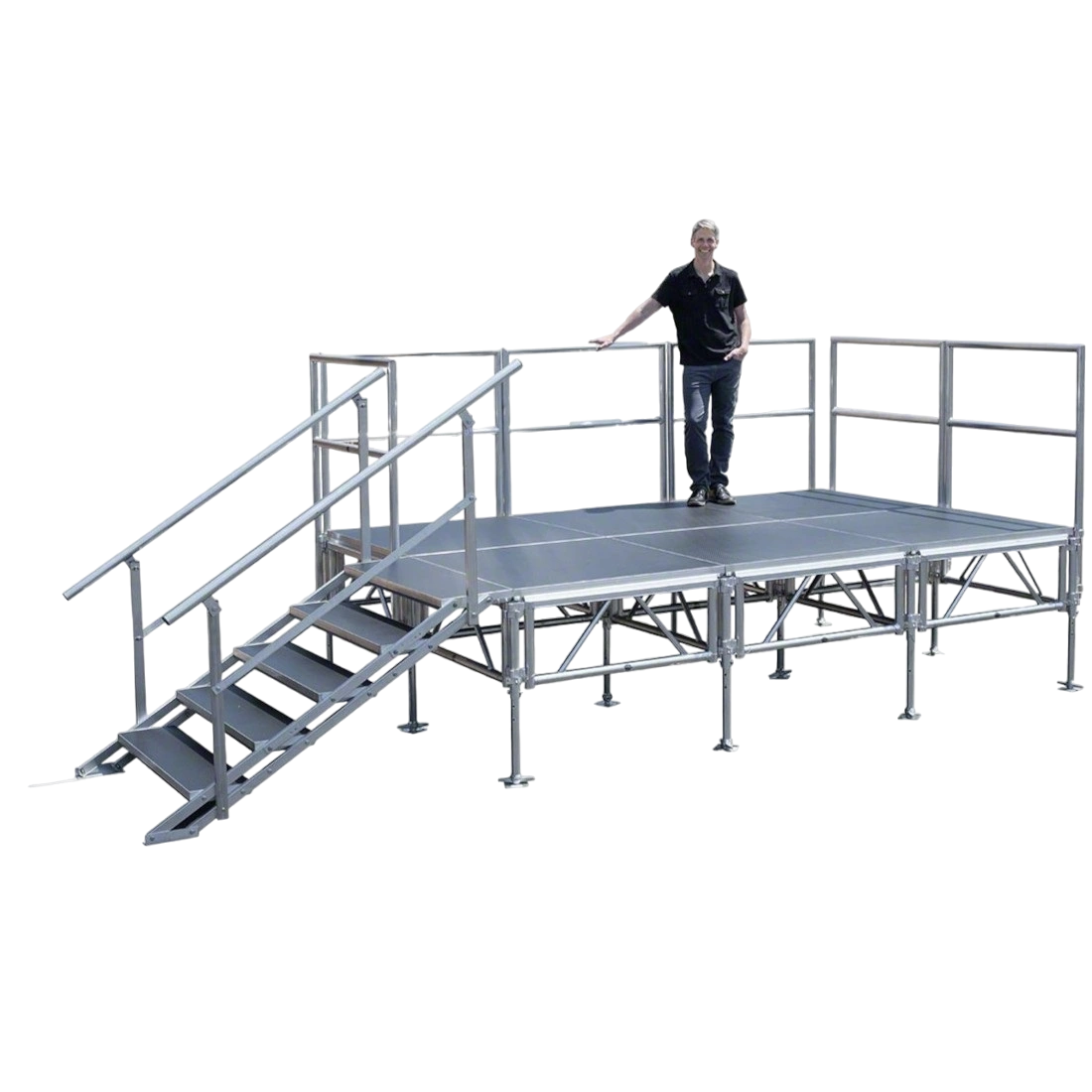

- Construction: Creating metal parts used in building and infrastructure projects.

- Consumer Goods: Producing various metal components for everyday products.

-

- Contact us today for a Quote and let us help you bring your projects to life with precision and excellence.

- The Raw Material Cost and Mold cost are extra and will be added to the Staping service cost based on the Metal type and thickness.

-

- You Can Email Us at Info@taimco.ca for any more information.

- Phone: +12899992334

Metal Stamping Service:

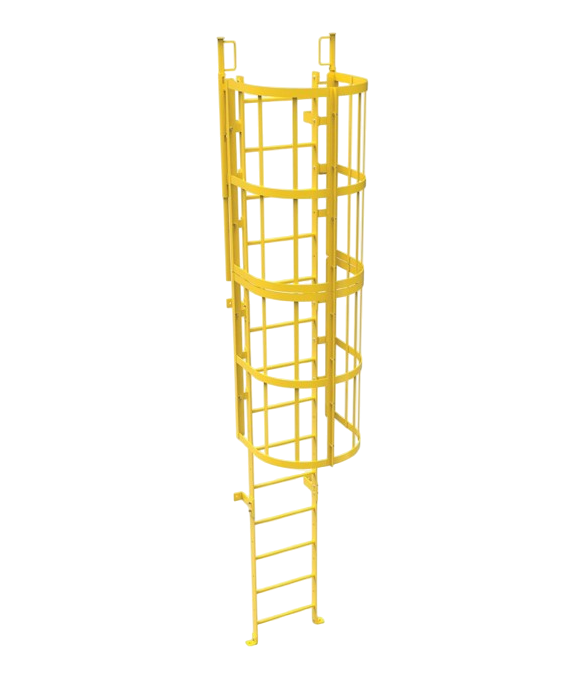

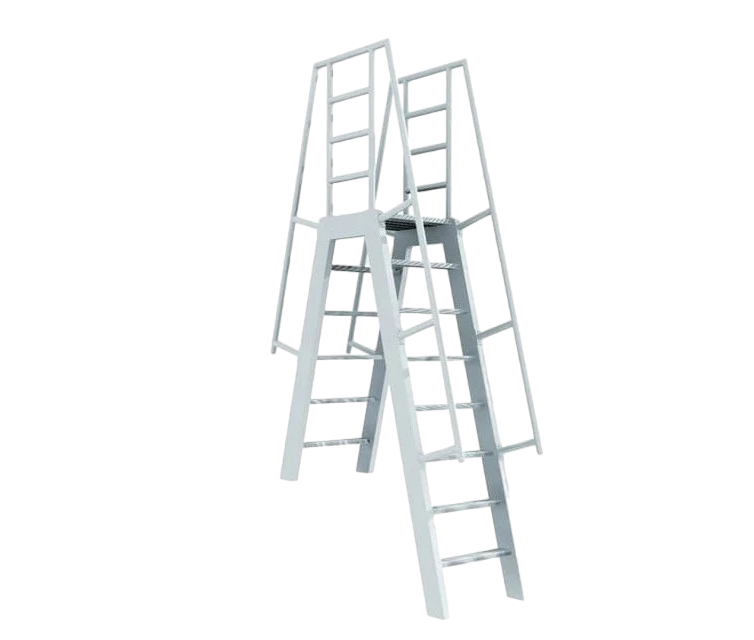

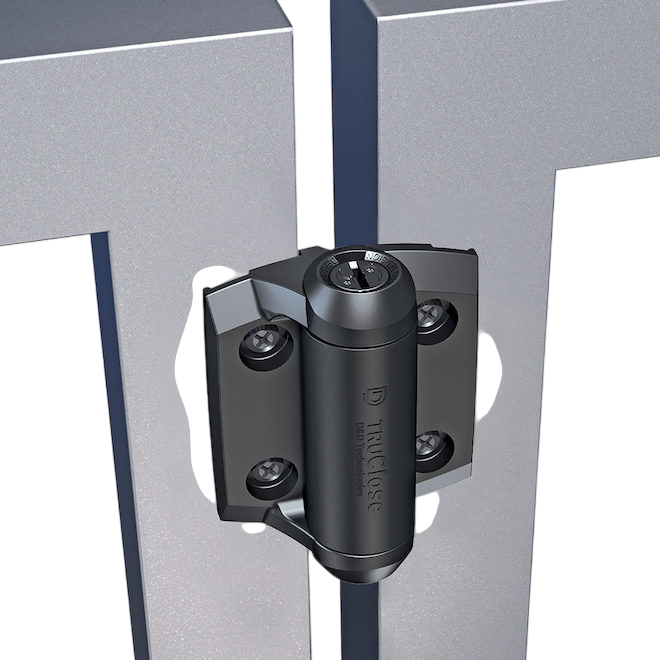

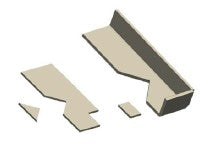

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. This process involves various techniques such as blanking, punching, bending, and piercing to form the desired components. Metal stamping is known for its precision and efficiency, making it ideal for producing high-volume parts with consistent quality.

Key Features of Metal Stamping Services

Industries We Can Help

Experience the difference with Taimco:

Dear valued customer,

We want to ensure your satisfaction every step of the way. As you may know, additional shipping charges are sometimes applied by third-party shipping companies for oversized or heavy items. These fees are based on factors like excess length, weight, and handling requirements.

Please rest assured that we do not profit from these charges; they are entirely passed on from the shipping companies. Our commitment to free shipping remains unwavering, and we appreciate your understanding.

Thank you for choosing us!

Email: info@taimco.ca

Get a quote in 24 hours!