Your cart is currently empty.

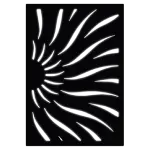

Architectural Powder Coating Model APC765

- Application Process:

- Powder coating involves applying a dry, electrostatically charged powder to the building’s surfaces.

- The coated surfaces are then cured under controlled heat, resulting in a uniform, durable finish.

- Benefits:

- Durability: Powder coatings offer superior longevity compared to traditional liquid coatings.

- Appearance: The smooth finish resists fading and wear, enhancing the building’s overall curb appeal.

- Environmental Considerations:

- Powder coating aligns with environmental regulations due to its solvent-free application process.

- Minimal environmental impact makes it an attractive choice for sustainable building practices.

- Send us your parts file for Quotation to info@taimco.ca, file formats can be ( .dxf - .dwg - .ai - .eps - .stp ).

- if you do not have the file we can help you build the part-cutting drawings file through the drawing design service we provide, Send us a sketch or template, and we'll help you convert it to a part.

- Custom Quote for projects including unique needs or requirements, we can provide a custom quote, Request Quote.

The exterior surfaces of buildings face relentless exposure to environmental factors such as UV radiation, precipitation, and wind. These elements, combined with potential human-induced damage, pose significant challenges for architects and building designers. To address these concerns effectively, the architectural industry increasingly relies on powder coatings. This specialized coating not only provides robust protection but also enhances the visual appeal of building exteriors. In this article, we explore the application, benefits, and considerations of architectural powder coating.

Introduction: The Battle Against Environmental Wear and Tear Buildings endure a constant assault from natural forces. Sunlight, rain, snow, and wind subject their surfaces to wear, rust, and corrosion. Additionally, human activities can contribute to surface damage.

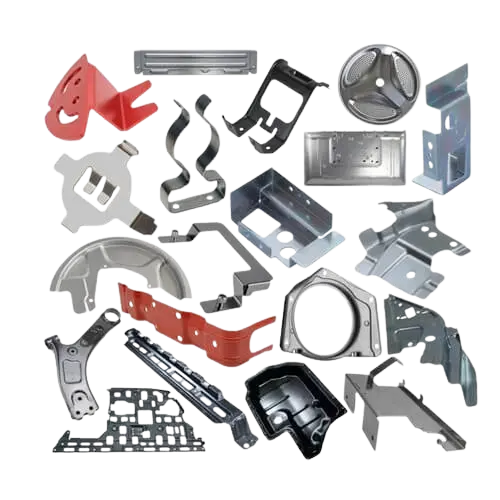

Powder Coating: A Dual Solution Architects turn to powder coatings as a versatile solution that combines protection and aesthetics. Here’s why:

Conclusion: A Lasting Investment By opting for architectural powder coating, building owners ensure both protection and aesthetics. The exterior surfaces withstand the elements, maintaining their appeal for years to come. Whether it’s a commercial high-rise or a residential complex, powder-coated buildings stand as resilient structures in the face of environmental challenges.

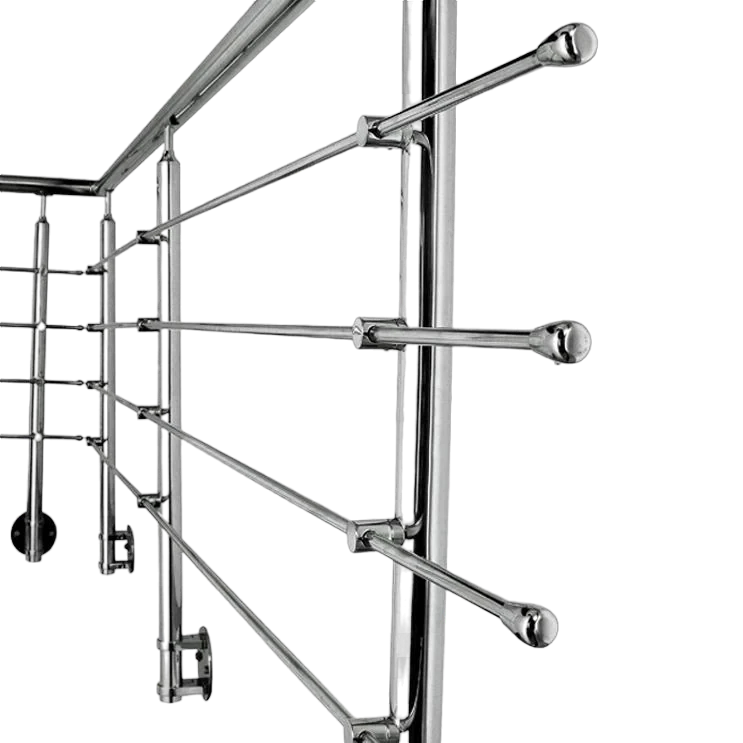

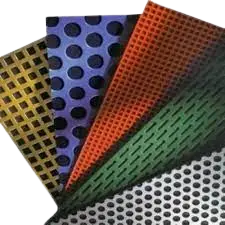

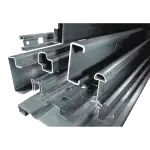

Material Available for powder coating:

Materials intended for powder coating must meet specific criteria: they must be capable of retaining an electrostatic charge and withstanding elevated curing temperatures. As a result of these prerequisites, aluminum, mild steel, and stainless steel emerge as the optimal choices for powder coating. Moreover, we have the flexibility to apply powder coating to these materials at various thickness levels.

| Material | Thickness |

| 5052 Aluminum | 0.063" - 0.55" |

| 6061 Aluminum | 0.063" - 0.55" |

| 7075 Aluminum | 0.125" - 0.25" |

| Mild Steel | 0.048" - 0.5" |

| G30 Galv Steel | 0.036" - 0.059" |

| G90 Galv Steel | 0.03" - 0.047" |

| 4130 Chromoly Steel | 0.05" - 0.25" |

| 304 Stainless Steel | 0.048" - 0.5" |

| 316 Stainless Steel | 0.06"- 0.25" |

How to Order Your Powder Coating Parts?

Contact Us Today To Get a Quote to learn more about our powder coating Complete services.

Email: info@taimco.ca

Get a quote in 24 hours!